Abstract

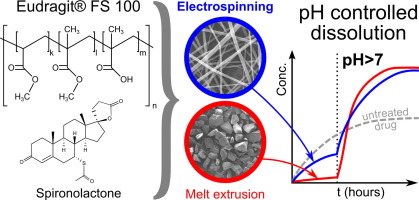

Eudragit® FS (EudFS), a novel anionic metachrylate terpolymer with pH dependent solubility was processed using electrospinning (ES) for the first time and melt extrusion (EX) for controlled delivery of a poorly water-soluble model drug, spironolactone (SPIR). Optimization of ES showed good spinnability of EudFS. Nanofibrous products could be obtained using fairly polar solvents (acetone, dichloromethane-ethanol (1:1), dimethylformamide). Drug-loaded nanofibers were prepared using novel alternating current electrospinning at multiple times higher throughput than direct current electrospinning. Melt extrusion proved to be also a feasible technique to prepare EudFS-based solid dispersions above 100°C. The viscoelasticity of EudFS melts was characterized in terms of temperature, frequency and heating time dependence. Solid state analyses revealed amorphous SPIR content in the electrospun fibers, however, signs of residual crystallinity could be detected in the extruded sample with 20% SPIR according to XRPD and EDS mapping. In vitro dissolution of the EudFS-based solid dispersions showed superior control of drug release compared to the physical mixture of crystalline SPIR and EudFS. At gastric pH where the polymer is insoluble the drug was more restrained in the ground extrudates than in the electrospun fibers. This state was followed by a quick burst as the pH rose to 7.4. EudFS, well-processed by electrospinning or melt extrusion, proved to be a promising matrix for oral drug delivery applications especially targeting the colon.