By the advent of continuous pharmaceutical manufacturing, fast and accurate characterization of product quality has become of a major interest. Although it also promotes the real-time release testing

approach, so far mainly content uniformity studies were performed by near-infrared (NIR) spectroscopy. This paper proposes the simultaneous application of NIR and Raman spectroscopy to

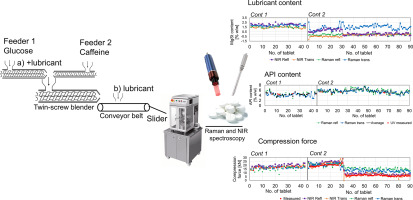

nondestructively analyze the critical quality attributes of continuously produced tablets in a real-time release testing procedure. A face-centered composite design was applied to determine the

impact of lubrication and compression force on the properties of a tablet formulation containing caffeine, glucose-monohydrate and magnesium stearate and to provide a systematic comparison of the

applicability of spectroscopic methods. Quantitative methods were developed to evaluate different lubrication approaches in a continuous blending and tableting line. The simultaneous application of

NIR and Raman spectroscopy revealed that NIR spectroscopy is more suitable to follow the changes of compression force, while Raman spectroscopy could be successfully applied for the detection of

overlubrication. The presented approach can be a part of a comprehensive real-time release strategy, where NIR and Raman spectroscopy provide complementary information about multiple critical quality

attributes, such as content uniformity, tablet hardness, friability and dissolution.