The development of oral dosage forms for poorly water-soluble active pharmaceutical ingredients (APIs) is a persistent challenge. A range of methods has been explored to address this issue, and amorphous solid dispersions (ASDs) have received increasing attention. ASDs are typically prepared by starting with a liquid precursor (a solution or melt) and applying energy for solidification. Many techniques can be used, with the emergence of electrospinning as a potent option in recent years. This method uses electrical energy to induce changes from liquid to solid.

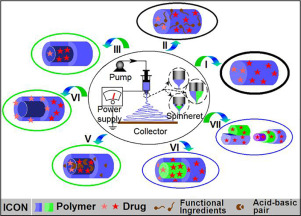

Through the direct applications of electrical energy, electrospinning can generate nanofiber-based ASDs from drug-loaded solutions, melts and melt-solutions. The technique can also be combined with other approaches using the application of mechanical, thermal or other energy sources. Electrospinning has numerous advantages over other approaches to produce ASDs. These advantages include extremely rapid drying speeds, ease of implentation, compatibility with a wide range of active ingredients (including those which are thermally labile), and the generation of products with large surface areas and high porosity. Furthermore, this technique exhibits the potential to create so-called ‘fifth-generation' ASDs with nanostructured architectures, such as core/shell or Janus systems and their combinations. These advanced systems can improve dissolution behaviour and provide programmable drug release profiles. Additionally, the fiber components and their spatial distributions can be precisely controlled.

Electrospun fiber-based ASDs can maintain an incorporated active ingredient in the amorphous physical form for prolonged periods of time because of their homogeneous drug distribution within the polymer matrix (typically they comprise solid solutions), and ability to inhibit molecular motion. These ASDs can be utilised to generate oral dosage forms for poorly water-soluble drugs, resulting in linear or multiple-phase release of one or more APIs. Electrospun ASDs can also be exploited as templates for manipulating molecular self-assembly, offering a bridge between ASDs and other types of dosage forms.

This review addresses the development, advantages and pharmaceutical applications of electrospinning for producing polymeric ASDs. Material preparation and analysis procedures are considered. The mechanisms through which performance has been improved are also discussed.