In the manufacture of tablets, especially in direct tableting processes, the flowability of excipient powders and formulated powders is one of the most important characteristics. In the past two decades, orally disintegrating tablets (ODTs) have been prepared as popular solid dosage forms for elderly patients. Many types of mannitol granules have been developed and marketed as new pharmaceutical excipients for ODTs, owing to the solubility and palatability of mannitol. Characterizing the flow behaviors of these mannitol granules is essential to their use.

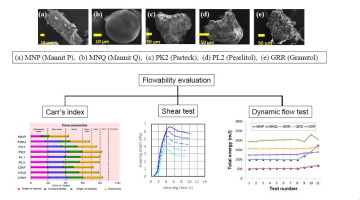

The flowability of mannitol excipients was the focus of the present study. A fine crystalline mannitol powder, eight commercial types of mannitol granules and four types of mannitol mixture granules were evaluated. Two flowability testers were used for comparing and analyzing the samples’ flowabilities. A variety of methodologies were used: an assessment using Carr’s index, a shear test and a dynamic flow test. Mannitol powder showed the lowest Carr’s index, meaning the lowest flowability. Spherical mannitol granules showed the lowest angle of internal friction in the shear test and extremely low basic flow energy in the dynamic flow test. Larger granules showed relatively high values for Carr’s index, but also a relatively high total flow energy.

Conclusion

The measurements in this study provide useful data for the use of mannitol granules and powder as pharmaceutical excipients. The flowability of mannitol granules was shown to be a quite complex phenomenon with various correlations with particle size, particle shape, and conditions of the particle surface. The comparison of three types of measurements gave better understanding of the flow behavior of mannitol granules in pharmaceutical manufacturing.

Spherical mannitol granules with the smallest particle size, MNQ, showed quite high flowability on each method: the lowest shear stress, the lowest angle of internal friction and the lowest BFE. The spherical shape of granules effectively improved the flowability of mannitol.

Crystalline powder with the smallest particle size, MNP, showed the lowest flowability for each method: the lowest Carr’s index, the highest cohesion, the highest shear stress, the lowest stability in dynamic flowability (FRI), and an extremely high SE. ・Comparing the results for GRF, GRS and GRR, the increase of size induced an increase of Carr’s index, and an increase of BFE. In other granules, the values of Carr’s index and total flow energy in dynamic tests also depended on the particle size. ・Evaluation of mannitol granules and mannitol mixture granules showed good flowability, suggesting that these granules are well designed.

Comparison of these flowability indices for powder and granules resulted in the following conclusions. The conventional measurements and Carr’s index were more affected by the particle size. The results of the shear test, i.e., shear stress and angle of internal friction, were affected by the shape of the particle more than the particle size. In the dynamic flow test, spherical-shape of granules had an extreme advantage in the case of BFE. The stability of the dynamic flow for flow speed was disturbed by the poor flowability of powders with small particle size and/or high cohesiveness.