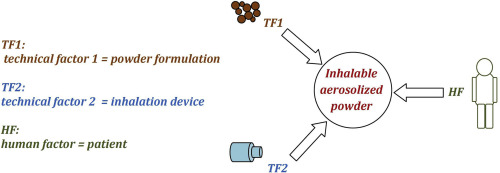

Development of bi-component generic orally inhaled product (OIP) delivered from dry powder inhaler (DPI) is challenging due to the necessity to demonstrate the similarity of size distribution of both APIs in inhaled aerosol. The effects of selected technical factors on OIP development are investigated. The Monodose inhalers with different aerodynamic resistance were used to aerosolize generic fluticasone/salmeterol formulations. Flow dynamics in the DPIs was analyzed during realistic use. The effects of lactose grade, capsule types and blending equipment on aerosol particle size were studied with compendial methods. The best dispersion of bi-component powder was obtained in a medium-resistant (∼0.108 hPa0.5 min L−1) Monodose DPI as compared to low- and high-resistant devices. All studied technological factors had influence on the fine particle dose of each API and fluticasone/salmeterol mass ratio. It was demonstrated that the selected Monodose inhaler in combination with the newly developed bi-component drug formulation was able to reproduce the quality of inhalable aerosol obtained from Diskus DPI. Since powder dispersion depends on the energy available in a single breath, an optimized DPI is needed in generic OIP. By adjusting several technological factors it is possible to obtain the reproducible product with the required dose of each aerosolized APIs.

- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact