Abstract

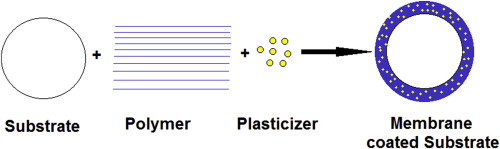

Extended drug delivery offers numerous benefits compared to immediate release dosage form. Membrane coating of immediate release dosage form is an effective means of producing an extended drug delivery system. Polymers when coated alone, have limited ability to form the rate controlling membrane with good mechanical properties. Addition of plasticizer is vital to the formation of a robust rate-controlling membrane. Plasticizers have the ability to interact with polymer chains, and provide desired flexibility, shock resistance, and smoothness to resultant system. In addition to the plasticizing effect they also play an important role in modulating drug release profiles. Selection of a plasticizer is critical for the stability of dosage form, the processing as well as in vivo performance. In this review article, various theoretical and practical methods for plasticizer selection have been discussed in detail and supported with the mechanism of action. Applications, where plasticizers are required in higher quantities, like dry coating, compression of coated pellets or required to form membrane to imbibe water i.e. osmotic drug delivery system are also discussed. Importantly, the selection criteria and quantity of plasticizer should also be considered from the regulatory perspective for an efficient drug product approval process.

Conclusion

Plasticizer plays an important role in film formation from a polymer coating system. For pharmaceutical use, there is a very limited pool of plasticizers that are acceptable from the regulatory aspects. For a given polymer system, plasticizers can be chosen alternatively to achieve similar thermal and mechanical film properties, however, the water uptake and water permeation studies, which affects the drug release, should be conducted systematically for proper selection of plasticizer.

Recommended for you