Abstract

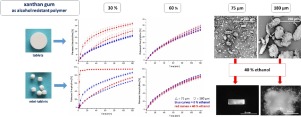

The vulnerability of controlled release formulations when co-ingested with alcohol represents a current major concern of regulatory agencies. Dose dumping might occur when drugs and/or excipients exhibit higher solubility in ethanolic solutions compared to water. In this study, xanthan gum was chosen as rate-controlling polymer for the development of alcohol resistant matrix formulations and theophylline as model drug. Two polymer particle sizes (75 and 180 µm) and concentrations (30 and 60% w/w) were used to assess their influence on the in-vitro drug release from directly compressed tablets and mini-tablets, in 0% and 40% ethanol for 2 hours (pH 1.2). For both, tablets and mini-tablets, by using 60% xanthan gum similar dissolution profiles in hydrous and hydroalcoholic media were obtained, independently of the polymer particle size. By decreasing the polymer concentration a risk of alcohol-induced dose dumping was recognised, however only when larger polymer particles were used. In particular, mini-tablets underwent disintegration and released the entire dose within 5 min in alcohol. Nevertheless, finer polymer particles used at lower concentration led to the formation of a more coherent and less porous gel layer and alcohol resistance could be tailored in regard to both matrix tablets and mini-tablets.

Conclusions

In the present study, the effect of ethanol in the dissolution media as well as xanthan gum particle size and xanthan gum concentration on the drug release rate was evaluated from matrix tablets and mini-tablets. Due to the decreased solubility of xanthan gum and the 2.8-fold increased solubility of theophylline in 40% ethanol, a faster drug release was observed in hydroalcoholic media, however only when the polymer was included in lower concentrations and in larger particle size. As a matter of fact, image analysis and gravimetrical studies could demonstrate how in ethanol larger polymer particles led to a higher dissolution media uptake and consequently a higher mass loss, causing therefore higher drug release at low xanthan gum concentration. In comparison to larger tablets, the mini-tablets showed a higher vulnerability to ethanol, due to the shorter diffusion path length, and led to alcohol-induced dose dumping with 30% polymer and larger particles. Interestingly, finer xanthan gum particles in all evaluated formulations allowed to tailor alcohol resistance, with similar dissolution profiles (f2 > 50) at both low and high polymer concentration. Robustness against alcohol could also be achived by increasing the amount of polymer. In this case the effect of the polymer particle size was negligible. According to this study, xanthan gum can be a suitable rate- controlling polymer for the development of alcohol resistant matrix tablets and mini-tablets, however finer polymer particles (< 75 μm) should be used in order to achieve this aim. Additional technological approaches should be, furthermore, considered in order to decrease the drug release from mini-tablets within 2 hours.