Abstract

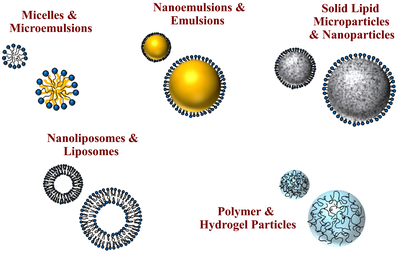

The design and development of nanoparticle- and microparticle-based delivery systems for the encapsulation, protection, and controlled release of active agents has grown considerably in the agrochemical, cosmetic, food, personal care, and pharmaceutical industries. These colloidal delivery systems can be utilized to overcome problems such as poor solubility, low activity, and chemical instability of active agents, as well as to create novel functional attributes such as controlled or targeted delivery. The purpose of this article is to develop a systematic approach, referred to as “delivery-by-design” (DbD), to make the design and fabrication process more efficient and effective. Initially, a brief review of some of the challenges associated with incorporating active agents into commercial products is given, and then an overview of different kinds of simple and complex colloidal delivery systems is given. The DbD approach is then presented as a series of stages: (1) definition of the molecular and physicochemical properties of the active agent; (2) definition of the required physicochemical, sensory, and functional attributes of the end-product; (3) specification of the required attributes of the colloidal delivery system; (4) specification of particle properties and delivery system selection; (5) optimization of delivery system manufacturing process; (6) establishment and implementation of delivery system testing protocol; and (7) optimization of delivery system performance. Utilization of the DbD approach may lead to more rapid design of efficacious and economically viable colloidal delivery systems for commercial applications.

Conclusions

There is growing interest in the utilization of colloidal delivery systems for the encapsulation, protection, and controlled release of active agents, such as drugs, nutraceuticals, vitamins, antimicrobials, antioxidants, colors, and flavors. However, many of the scientific articles published in this area do not consider the practical aspects of designing and fabricating colloidal delivery systems, so that the systems developed have little economic feasibility. This article develops a comprehensive and systematic approach for developing colloidal delivery systems for specific functional applications. This DbD approach begins by specifying the most important physicochemical properties and functional attributes required for both the active agent and the end-product. It then specifies the properties that any colloidal delivery system must possess to meet these requirements, which enables one to focus on those delivery systems that are the most appropriate for a particular application. Optimization of a commercially feasible fabrication method to manufacture the colloidal delivery system is then emphasized. Finally, the DbD approach stresses the need for developing a systematic approach to characterizing and refining the properties of the colloidal delivery system during the development and production stage. The application of this approach by food scientists should lead to the creation of more effective and commercially viable colloidal delivery systems for particular applications.