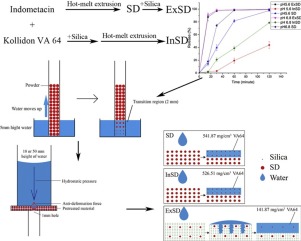

The purpose of this work was to investigate the effect on the dissolution behavior when silica was added in different ways. The solid dispersion was prepared by hot-melt extrusion (HME) using indomethacin (IND) as a model drug and Kollidon VA64 as a carrier. In order to change the dissolution behavior, the silica was added during or after the HME respectively, to obtain the corresponding silica internal-added solid dispersion (InSD) and silica external-added solid dispersion (ExSD). According to the results, the internal-added silicon dioxide could reduce the dissolution rate from 66.91%/h to 24.12%/h and the water infiltration rate from 0.37 mm/h to 0.16 mm/h in the phosphate buffer solution (PBS) of pH 6.8, so the formulation of InSD had a significant sustained release effect. But the infiltration rate of the ExSD was increased to 13.22 mm/h when silica was added external, and the density of VA64 in the powder was decreased from 541.87 mg/cm3 to 141.87 mg/cm3, leading to a weak resistance to the external force, and the powder was easy to be dispersed after wetted by water so that the formulation of ExSD had a relatively higher dissolution rate. This phenomenon was more visible when the phosphate buffer solution was changed to pH 5.6 in which the API was more difficult to be dissolved. Accordingly, different addition ways of aerosil would change release behavior of the HME preparation.

- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact