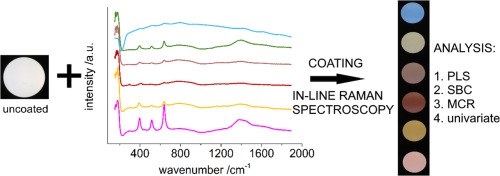

Endpoints of coating processes for colored tablets were determined using in-line Raman spectroscopy. Coatings were performed with six commercially available formulations of pink, yellow, red, beige,

green and blue color. The coatings were comprising pigments and/or dyes, some causing fluorescence and interfering the Raman signal. Using non-contact optics, a Raman probe was used as process

analytical technology (PAT) tool, and acquired spectra were correlated to the sprayed mass of aqueous coating suspension. Process endpoints were determined using univariate (UV) data analysis and

three multivariate analysis methods, namely Projection to Latent Structures (PLS)-regression, Science-Based Calibration (SBC) and Multivariate Curve Resolution (MCR). The methods were compared

regarding model performance parameters. The endpoints of all coating experiments could be predicted until a total coating time of 50 minutes corresponding to coating thicknesses between 21 and

38 µm, depending on the density of the coat formulation. With the exception of SBC, all calibration methods resulted in R2 values higher than 0.9. Additionally, the methods were evaluated regarding their capability for

in-line process monitoring. For each color, at least two methods were feasible to do this. Overall, PLS-regression led to best model performance parameters.

- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

Write a comment