Pharmaceutical pellets are spherical agglomerates manufactured in extrusion/spheronization process. The composition of the pellets, the amount of active pharmaceutical ingredient (API) and the type

of used excipients have an influence on the shape and quality of dosage form. A proper quality of the pellets can also be achieved by identifying the most important technological process parameters.

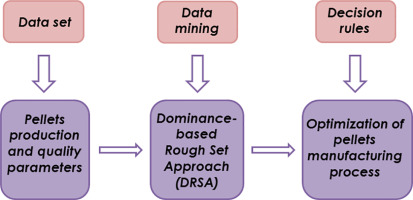

In this paper, a knowledge discovery method, called dominance-based rough set approach (DRSA) has been applied to evaluate critical process parameters in pellets manufacturing. For this purpose, a

set of condition attributes (amount of API; type and amount of excipient used; process parameters such as screw and rotation speed, time and temperature of spheronization) and a decision attribute

(quality of the pellets defined by the aspect ratio) were used to set up an information system. The DRSA analysis allowed to induce decision rules containing information about process parameters

which have a significant impact on the quality of manufactured pellets. Those rules can be used to optimize the process of pellets manufacturing.

- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact