Combined micro- and nanosystems are appealing for pulmonary protein delivery, fulfilling the specific physiological requirements for efficient outcomes in-vivo.

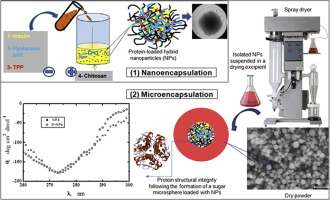

However, fabrication of protein formulations may impose stresses perturbing protein conformational stability and, hence, biological activity. Herein, a protein, insulin (INS), was nanoencapsulated

inside chitosan nanoparticles (CS NPs) by ionic gelation. By spray drying, the resultant protein-loaded NPs were further encapsulated with a thermoprotectant into powders bearing adequate aerodynamic

properties for lung delivery. Structural modifications and interactions of the protein/carrier system were investigated following processing, with special emphasis on protein integrity. Accordingly,

physicochemical, elemental, structural and thermal experiments were performed. The analyses revealed the localization of a proportion of the protein on the NPs’ surface following nanoencapsulation,

and the involved molecular interactions between the NPs and thermoprotectant after microencapsulation. Protein integrity was conserved throughout the preparation processes. This highlights the

non-invasiveness of the fabrication techniques, particularly spray drying, for preparing micro-nanosystems for effective administration of inhalable macromolecules.