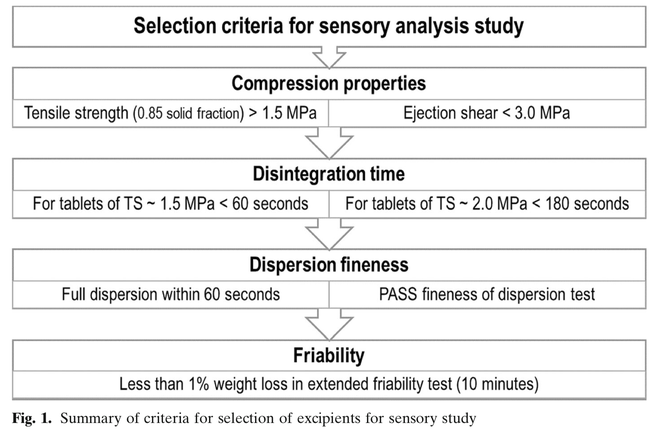

Palatability and patient acceptability are critical attributes of dispersible tablet formulation. Co-processed excipients could provide improved organoleptic profile due to rational choice of excipients and manufacturing techniques. The aim of this study was to identify the most suitable co-processed excipient to use within directly compressible dispersible tablet formulations. Nine excipients, selected based on successful manufacturability, were investigated in a randomised, preference and acceptability testing in 24 healthy adult volunteers. Excipients were classified in order of preference as follows (from most preferred): SmartEx QD100 > F-Melt Type C > F-Melt Type M > MicroceLac > Ludiflash > CombiLac > Pharmaburst 500 > Avicel HFE-102 > Avicel PH-102. Broad differences were identified in terms of acceptability, with SmartEx QD100 being ‘very acceptable’, F-Melt Type C, F-Melt Type M and MicroceLac being ‘acceptable’, Ludiflash, CombiLac and Pharmaburst 500 being ‘neutral’ and Avicel products being ‘very unacceptable’ based on ratings using five-point hedonic scales. Organoleptic differences were ascribed to different composition and physical properties of excipients, resulting in dissimilar taste and mouth-feel. Excipients with particle size in water larger than 200–250 μm were considered poorly acceptable, which supports the use of this value as a threshold for maximum particle size of dispersible formulation. The most promising co-processed excipients for directly compressible dispersible tablets were successfully identified.

- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact