This study was performed to investigate how increasing the active pharmaceutical ingredient (API) content within a formulation affects the dispersion of particles and the aerosol performance efficiency of a carrier based dry powder inhalable (DPI) formulation, using a custom dry powder inhaler (DPI) development rig.

Methods

Five formulations with varying concentrations of API beclomethasone dipropionate (BDP) between 1% and 30% (w/w) were formulated as a multi-component carrier system containing coarse lactose and fine lactose with magnesium stearate. The morphology of the formulation and each component were investigated using scanning electron micrographs while the particle size was measured by laser diffraction. The aerosol performance, in terms of aerodynamic diameter, was assessed using the British pharmacopeia Apparatus E cascade impactor (Next generation impactor). Chemical analysis of the API was observed by high performance liquid chromatography (HPLC).

Results

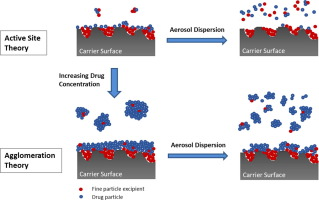

Increasing the concentration of BDP in the blend resulted in increasing numbers and size of individual agglomerates and densely packed BDP multi-layers on the surface of the lactose carrier. BDP present within the multi-layer did not disperse as individual primary particles but as dense agglomerates, which led to a decrease in aerosol performance and increased percentage of BDP deposition within the Apparatus E induction port and pre-separator.

Conclusion

As the BDP concentration in the blends increases, aerosol performance of the formulation decreases, in an inversely proportional manner. Concurrently, the percentage of API deposition in the induction port and pre-separator could also be linked to the amount of micronized particles (BDP and Micronized composite carrier) present in the formulation. The effect of such dose increase on the behaviour of aerosol dispersion was investigated to gain greater insight in the development and optimisation of higher dosed carrier-based formulations.