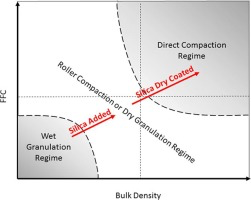

It has been shown that dry coating cohesive active pharmaceutical ingredients (APIs) with nano-silica can improve packing and flow of their blends, facilitating high speed direct compressiontableting. This paper examines the broader scope and generality of previous work by examining three fine APIs; micronized Acetaminophen (mAPAP), coarse Acetaminophen (cAPAP) and micronized Ibuprofen(mIBU), and considers dry coating with both hydrophobic or hydrophilic nano-silica to examine the effect not only on packing density and flow of their blends, but also dissolution and tensilestrength of their tablets. The impact of the excipient size on blend and tablet properties are also investigated, indicating blend flow is most improved when matching API particle size with excipientparticle size. In all cases where the API is dry coated, the blend packing and flow improve, so as to suggest such high drug loaded blends could enable direct compression. Using dry coated API alongwith finer excipients in blends lead to improved hardness of the corresponding tablets. Interestingly, dissolution profiles show dry coated API tablets generally have faster dissolution rates,regardless of silica hydrophilicity, suggesting API powder deagglomeration via nano-silica coating plays a crucial role. The most significant conclusion is that, although there are differences inproperties of blends that depend on the API, hydrophobic or hydrophilic nano-silica coating, as well as large or fine excipients, in all cases, dry coating of APIs significantly improves the possibility of using the specific blend at high drug loading in direct compression tableting.