Fused deposition modelling (FDM) 3D printing has shown the most immediate potential for on-demand dose personalisation to suit particular patient's needs. However, FDM 3D printing often involves

employing a relatively large molecular weight thermoplastic polymer and results in extended release pattern. It is therefore essential to fast-track drug release from the 3D printed objects. This

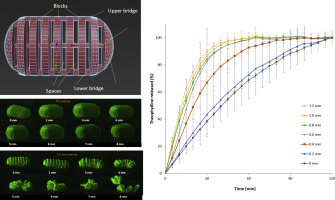

work employed an innovative design approach of tablets with unique built-in gaps (Gaplets) with the aim of accelerating drug release. The novel tablet design is composed of 9 repeating units (blocks)

connected with 3 bridges to allow the generation of 8 gaps. The impact of size of the block, the number of bridges and the spacing between different blocks were investigated. Increasing the

inter-block spaces reduced mechanical resistance of the unit, however, tablets continued to meet pharmacopeial standards for tablet's friability. Upon introduction into gastric medium, 1 mm spaces

tablet broke into mini-structures within 4 min and met the USP criteria of immediate release products (86.7% drug release at 30 min). Real-time ultraviolet (UV) imaging indicated that the cellulosic

matrix has expanded due to swelling of HPC upon introduction to dissolution medium. This was followed by a steady erosion of the polymeric matrix at a rate of 8 μm/min. The design approach was more

efficient than formulation approach of adding disintegrants to accelerate tablet disintegration and drug release. This work provides a unique example where computer-aided design was instrumental at

modifying the performance of solid dosage forms. Such an example may serve as a foundation for a new generation of dosage forms with complicated geometric structures to achieve functionality that are

usually reached by formulation approach.