As the pharmaceutical industry modernizes its manufacturing practices and incorporates more efficient processing approaches, it is important to reevaluate which process design elements affect product

quality and the means to study these systems. The purpose of this work is to provide insight on a methodology to correlate the effect of raw material properties to equipment and process performance

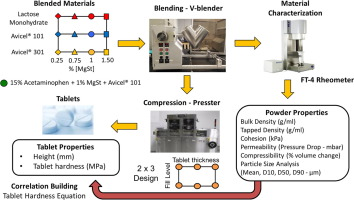

using both data-driven and semi-empirical models. In this work, lubricated blends of pharmaceutically-relevant materials were made using varying levels of magnesium stearate, ranging from 0.25-1.5%.

Materials characterization (e.g., compressibility, permeability, density, particle size) was performed for all materials and blends. The blends were compressed using a two by three experimental

design, varying tablet fill cam depth and tablet thickness, respectively. Tablet properties (e.g., weight, tensile strength, and thickness) were collected for all tablets. Using the collected tablet

property results, models coefficients for the semi-empirical Kuentz and Leuenberger equation, which relates the tablet tensile strength to changes in porosity, were regressed. Empirical models were

then developed to correlate the values of the Kuentz and Leuenberger equation coefficients to the blend material properties. The empirical models were then used in conjunction with the Kuentz and

Leuenberger equation to evaluate the compression design and operational space, accounting for material properties. This proof of concept work aimed at developing correlations between raw material

properties and unit operation models can aid process development, especially in design space characterization and robustness analysis.