Abstract

Faecalibacterium prausnitzii was previously recognized for its intestinal anti-inflammatory activities and it has been shown less abundant in patients with chronic intestinal diseases. However, the main problems encountered in the use of this interesting anaerobic microorganism are firstly its high sensitivity to the oxygen and secondly, its ability to reach the large intestine alive as targeted site. The aim of this study was to investigate the effect of direct compression on the viability of this probiotic strain after different compression pressure and storage using three different excipients (MCC, HPMC and HPMCP). The effect of compression process on cell viability was studied and a strategy was proposed to improve probiotic viability. Results showed that cell viability decreased almost linearly with compression pressure. MCC and HPMC seemed the most favorable carriers and after storage, each tablet exhibited a survival above108 CFU. Storage stability was obtained with a pressure of 201 MPa after 28 days at 25°C, in anaerobic condition and with 11% relative humidity. Compression after a pre-consolidated stage improved clearly the survival rate due to lower temperature increase and lower shearing force. Thus, direct compression seems to be suitable in producing probiotics tablets with extremely oxygen-sensitive strains, and could provide sufficient protection during storage to expect therapeutic efficiency.

Conclusion

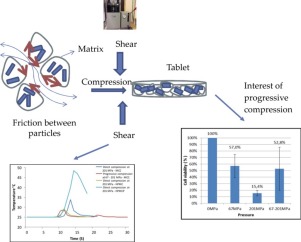

Development of tablets is considered as a good way to deliver probiotic strains to patients for therapeutic use. However, the compression experimental design could have a huge influence on viability of bacteria. Suitable conditions to stabilize F. prausnitzii, an extremely sensitive to oxygen probiotic bacteria, were studied by direct compression. Formulation was an important parameter. In addition to the nature of excipient, the ratio bacteria/excipient must be carefully chosen to achieve a suitable balance between technological needs and the survival of bacteria. Indeed, the increase of the compression pressure decreased the survival rate of probiotics but improved the storage stability over time. The decrease of bacterial viability could be linked to shear forces involved with a subsequent increase of temperature inside the compression die during the process. So, progressive compression provided better survival rate of probiotics, showing the interest of a pre-consolidated stage even during storage. All these results highlight the great potential of direct compression as a strategy to produce probiotic tablets, even with an anaerobic probiotic strain. Further works are now needed in order to optimize the manufacturing process for large-scale production, particularly to find an alternative to anaerobic chamber and to develop an optimal coating to protect bacteria against gastric acidity.

Recommended for you