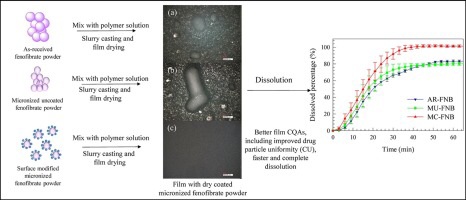

Recent work has established polymer strip films as a robust platform for delivery of poorly water-soluble drugs via slurry casting, in particular using stable drug nanosuspensions. Here, a simpler,

robust method to directly incorporate dry micronized poorly water-soluble drug, fenofibrate (FNB), is introduced. As a major novelty, simultaneous surface modification using hydrophilic silica along

with micronization was done using fluid energy mill (FEM) in order to reduce FNB hydrophobicity and powder agglomeration. It is hypothesized that silica coating promotes easy, uniform dispersion of

micronized and coated FNB (MC-FNB) during direct mixing with aqueous hydroxypropyl methylcellulose (HPMC-E15LV) and glycerin solutions. Uniform dispersion leads to improved film critical quality

attributes (CQAs) such as appearance, drug content uniformity and drug dissolution. The impact of polymer solution viscosity (low and high), mixer type (low versus high shear), and FNB surface

modification on film CQAs were also assessed. Films with as-received FNB (AR-FNB) and micronized uncoated FNB (MU-FNB) were prepared as control. When MC-FNB powders were used, films exhibited

improved appearance (thickness uniformity, visible lumps/agglomerates), better drug content uniformity (expressed as relative standard deviation), fast and immediate drug release, and enhanced

mechanical properties (tensile strength, elongation percentage), regardless of the polymer solution viscosity or mixer type. These results compare favorably with those reported using nanosuspensions

of FNB, establishing the feasibility of directly incorporating surface modified-micronized poorly water-soluble drug powders in film manufacturing.