Abstract

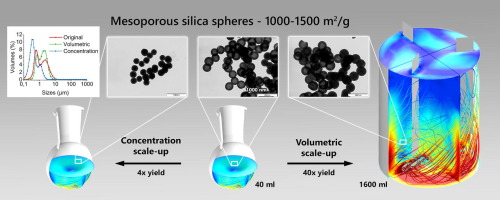

Despite the wide application interest in mesoporous silica micro- and nano-particles and a number of synthesis routes reported in the literature, the question of chemical engineering scale-up of the synthetic routes has rarely been addressed. The present work reports the results of an experimental and computational study of batch scale-up by a factor of 40x in the specific case of two types of dense and hollow mesoporous silica microparticles produced by the hydrolysis of tetraethoxysilane (TEOS) using a CTAB surfactant template. Volume and concentration based scale-up approaches have been investigated and systematically compared using a similarity index that included parameters related to the particle size distribution (d10, d50, d90) and pore structure (mean pore diameter, specific surface area, total pore volume, sorption hysteresis loop). The particle size distribution was found to be dependent mainly on the hydrodynamic conditions, expressed by the homogenization time, while the pore structure and the overall yield of the process were found to depend mainly on the CTAB/TEOS ratio. Overall, successful scale-up criteria in both volume and concentration based approaches have been identified.

Conclusion

The scale-up of a process for the soft-templated synthesis of mesoporous silica particles by the hydrolysis of TEOS was investigated experimentally using two different approaches. In a volume based scale-up, the total yield of SiO2 particles was increased almost 40-fold, from 0.10 g (conversion 77 %) to 4.0 g (conversion 72 %) per batch in the case of hollow-core particles and from 0.12 g (conversion 90 %) to 5.0 g (conversion 85 %) in the case of dense-core particles. The stirring conditions during the synthesis (expressed by the batch homogenization time) were identified as the key parameter that determines successful scale-up, enabling both particle size distribution and internal pore structure to be preserved.

With the reagent concentration based scale-up, the total yield was increased 16-fold (4-fold from batch size enlargement and 4-fold from a higher reagent concentration) from 0.10 g (conversion 77 %) to 1.52 g (conversion 71 %) per batch. The particles obtained from the synthesis using a higher concentration of reagents lost their hollow structure, but their pore morphology was retained, the particles had a higher specific surface area and an increased mesopore volume compared to the original synthesis. Moreover, the extent of primary particle aggregation was lower.

Recommended for you

- Accelerating pharmaceutical development through predictive stability approaches

- AFFINISOL™ HPMC HME for Hot Melt Extrusion

- Excipient DMF 3rd Quarter 2017