Abstract

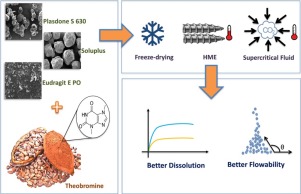

The aim of this study was to improve the pharmaceutical properties of theobromine (TB), particularly its flowability and dissolution rate, by preparing solid dispersions using different technologies (hot melt extrusion—HME, freeze-drying—FD, and supercritical fluid—SF) as well as testing different hydrophilic polymeric matrixes (Eudragit™ E, Plasdone™ S and Soluplus™). Samples were characterized by means of physicochemical assays, along with flow measurements and determination of dissolution profiles. X-ray diffraction data revealed the maintenance of original drug crystalline phase in all solid dispersions produced, nevertheless thermal and spectroscopy assays evidenced drug–polymer interactions, especially for samples produced using HME. The drug content was preserved after processing and no signal of decomposition or instability was verified. Pharmaceutical performance of solid dispersions was markedly influenced by the processing method. Systems obtained using HME were distinguished by having better flowability (angle of spatula <40° and compressibility <11%) and dissolution properties (approximately 75% of dissolution efficiency against 55% of TB as supplied). On the other hand, FD and SF also improved TB dissolution profile, but this enhancement depended on the polymer used. Eudragit™ E proved to be the most versatile material with equivalent dissolution performance using the three methods (dissolution efficiency >70%). In conclusion, the increasing of TB functional properties could bring good perspectives of bioavailability enhancement with prospects of broadening this drug insertion into the pharmaceutical market.

Conclusion

TB solid dispersions maintained drug original crystalline phase regardless the preparation method or the polymeric matrix used. Still, systems physicochemical characteriza- tion indicated the occurrence of drug–polymer intermolecular interactions, which improved flow and enhanced TB dis- solution. Pharmaceutical performance of solid dispersions was markedly influenced by the processing method. Systems obtained using HME were distinguished by having better flowability and dissolution properties with all tested polymers.

On the other hand, FD and SF also improved TB dissolution profile, but this enhancement depended on the polymer used. EuE proved to be the most versatile material with equivalent performance with the three solid dispersion methods. The increasing of TB functional properties exhibited in this work brings good perspectives of bioavailability enhancement with prospects of broadening this drug insertion into the pharmaceutical market.