Background: Generally, the preparation of spray-dried microspheres is strongly affected by the process parameters. Particle size and production yield are mainly in fluenced by the spraying solution concentration and the pump rate of the spray dryer.

Aim: The aim of this study was to assess optimum spray drying parameters - polymer concentration and pump rate required for the production of chitosan microspheres with high production yield and targeted for nasal administration particle size.

Materials and methods: Full 32 factorial design was used to study the investi- gated parameters. Three different concentrations of the chitosan solution were selected: a low concentration of 1%, average concentration of 1.5% and high con- centration of 2%. The rate of the peristaltic pump was also varied at three levels: low rate of 10%, medium rate of 14% and high rate of 18%.

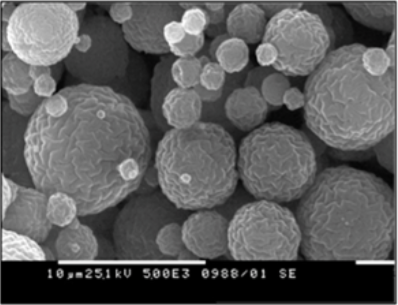

Results: Nine models of chitosan microspheres were formulated and characterized in terms of shape, surface morphology, size, particle size distribution and production yield. The particles obtained from 2% chitosan solutions, sprayed at 10% pump rate were of the highest yield (64.33%) and appropriate for nasal adminis- tration median diameter (3,434 μm).

Conclusion: The two investigated spray-drying parameters interact with each other and their influence on the production yield and the size of the chitosan microspheres should be evaluated together, instead of one at a time. The assessed process parameters allow the production of chitosan microparticles with high yield and desirable characteristics (size, size distribution and shape) for intranasal delivery.

Folia Medica 2017;59(3):310-317. dos: 10.1515/folmed-2017-0037

https://www.degruyter.com/downloadpdf/j/folmed.2017.59.issue-3/folmed-2017-0037/folmed-2017-0037.pdf