Increasing knowledge about the human microbiome has led to a growing awareness of the potential of applying probiotics to improve our health. The pharmaceutical industry shows an emerging interest in

pharmaceutical formulations containing these beneficial microbes, the so-called pharmabiotics. An important manufacturing step is the drying of the probiotics, as this can increase the stability and

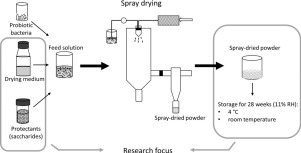

shelf life of the finished pharmabiotic product. Unfortunately, drying also puts stress on microbial cells, thus causing a decrease in viability. We aimed to examine the effect of different drying

media and protective excipients on the viability of the prototype probiotic strain Lactobacillus rhamnosus GG after spray drying and

during subsequent storage for 28 weeks. The presence of phosphates in the drying medium showed to have a superior protective effect, especially during long-term storage at room temperature. Addition

of lactose or trehalose resulted in significantly improved survival rates after drying as well as during long-term storage for the tested excipients. Both disaccharides are characterized by a high

glass transition temperature. Maltodextrin showed less protective capacities compared to lactose and trehalose in all tested conditions. The usage of mannitol or dextran resulted in sticky powders

and low yields, so further testing was not possible. In addition to optimizing the viability, future research will also explore the functionality of cellular probiotic components after spray drying

in order to safeguard the probiotic activity of the formulated pharmabiotics.

- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact