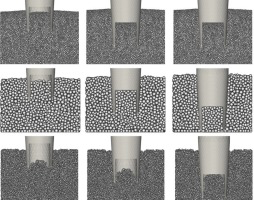

Filling a dosator nozzle moving into a powder bed was investigated using the Discrete Element Method (DEM). Various particle diameters and contact properties were modeled. The simulations

qualitatively showed the influence of powder properties on the amount of dosed powder. Two factors that influence the dosed mass were observed. First, the ratio between the particle and dosator

diameters affects the packing of particles inside the dosator chamber. Second, the flow behavior of the powder significantly modifies its filling and compression behavior. Cohesive powders pack less

densely inside the powder bed, which could lead to a lower amount of dosed powder. In contrast, cohesive powders are compressed more during dosing and the density inside the dosator chamber increases

during the dosing process. Since the simulation of fine cohesive powders is numerically impossible due to a high number of particles and small simulation time steps, we applied a simple method for

particle scaling to acquire a qualitative understanding of the filling behavior of coarse and fine powders.

- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact