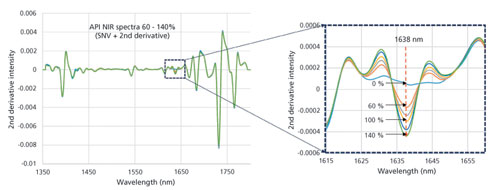

Within the pharmaceutical industry, inline near infrared (NIR) spectroscopy is one of the most commonly applied process analytical technologies to monitor content uniformity of powder blends (1).

Inline NIR provides direct insight into blending operations with respect to the degree of uniformity of the ingredient of interest either for process development or control during commercial

manufacturing. A quantitative calibration for a specific ingredient may be applied to predict the content of small fractions of the powder blend during the blend process, such as for every revolution

in the case of a rotary blender. The actual size and sampled volume of the powder blend is an important variable for interpretation of NIR results.

- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact