For the development of this excipient for direct compression no chemical modification was applied. The enhanced functionality enabling a nearly zero order release was achieved by techniques such as physical mixing, high shear mixer granulation and spray drying.

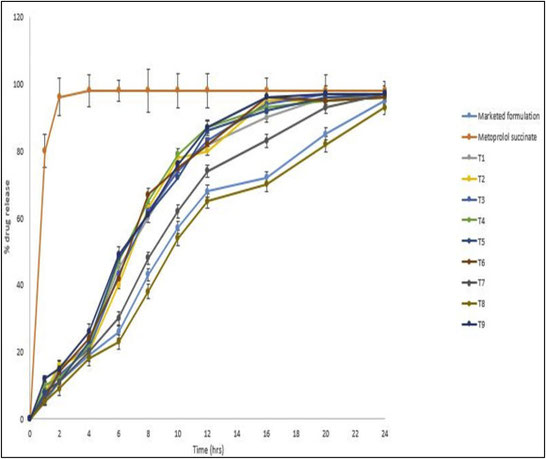

Co-processed excipient was developed by using release retarding polymer Eudragit RSPO, separately, in combination with different concentration of hydroxyl propyl methyl cellulose 100 cps (Methocel K100 LV, HPMC), ethyl cellulose (Ethocel N50, EC) and hydroxyl propyl cellulose (Klucel EF, HPC). All co-processed excipients were evaluated for their flow properties in terms of angle of repose, bulk density, tapped density, compressibility index and Hausner's ratio. Out of eighteen combinations, the nine co-processed excipients exhibited promising flow properties were found suitable for direct compression and formulated as tablets. Metoprolol succinate, a BCS Class I drug, was selected as a model drug and the formulation was developed employing direct compression approach. The developed tablets were evaluated for physical parameters like uniformity of weight, thickness, hardness, friability and assay. In vitro dissolution study confirms that formulation prepared using co-processed excipient showed sustained drug release. The optimized tablet formulation was characterized by DSC, FTIR and PXRD which confirms the absence of any chemical change during co-processing. The optimized formulation was kept for stability study for six months as per ICH guidelines and found to be stable. In vivo pharmacokinetic study of optimized formulation in rats showed similar pharmacokinetic behaviour as was observed with the marketed brand. Study revealed that co-processed excipient has advantage over polymers with single property and can be utilised for sustained release formulation.

a Sidhhant College of Pharmacy, Sudumbare, Pune, India

b School of Pharmaceutical Sciences, Jaipur National University, Jaipur, India

https://doi.org/10.1016/j.fjps.2017.07.004