Abstract

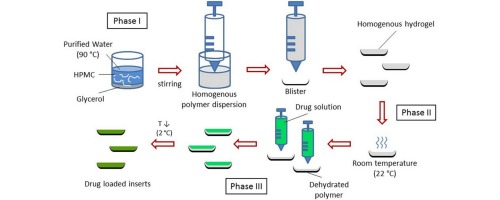

A methodology was developed and optimised for the preparation of a new drug delivery system (DDS) with sustained release properties to allow ocular protein delivery and to limit destructive production steps during manufacturing. Elevated temperatures, shear forces and an oxidative environment should be avoided in order to prevent denaturation or oxidation of proteins. An aqueous HPMC solution was prepared using heat and casted into small semi-rod-shaped PVC blisters. The polymer solution was allowed to cool down and was partially dehydrated at room temperature. A drug solution containing glycerol, drug and water was subsequently added to rehydrate the partially dehydrated polymer matrix at a temperature of 2 °C. Several parameters of the production process were varied to determine their influence on the release kinetics from HPMC inserts from three different molecules of different molecular weight. This production method was further optimised in order to shorten the rehydration time from weeks to days, while eliminating heat and shear forces on the selected drug molecules sodium fluorescein, lysozyme and albumin. Slow release kinetics were achieved for sodium fluorescein and lysozyme as model drug molecules. The higher molecular weight of albumin prevented a good penetration into the insert during the rehydration process resulting in predominantly burst release. The biocompatibility of a viscous HPMC solution was evaluated on SV40-human corneal epithelial cells with PrestoBlue® and no cytotoxic effects were observed.