Abstract

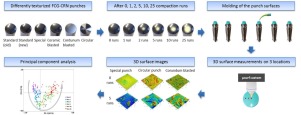

The surface quality of tablets is strongly related to the surface quality of the tablet punch. Therefore, regular control of the punch surfaces is needed to determine the surface properties, the wear status and sticking tendency of the punches. The aim of the present study was to develop and evaluate a new technique to visualize and evaluate tablet punch surfaces using high-resolution impression molding combined with 3D surface analysis. Standardized 3D surface texture parameters were analyzed by principal component analysis (PCA) to characterized differently surface‐modified punches, punches with different wear status and the sticking pattern on the punch surfaces. It could be shown that the presented technique was precise enough to differentiate between differently coated and texturized punches, to evaluate the abrasive wear status of the investigated punches, and to visualize and assess punch tip sticking behavior. In conclusion, this novel technique may serve as a valuable tool for systematic punch surface characterization, wear status check‐up and optimization of the punch surface quality e.g. for improvement of the anti‐sticking behavior.